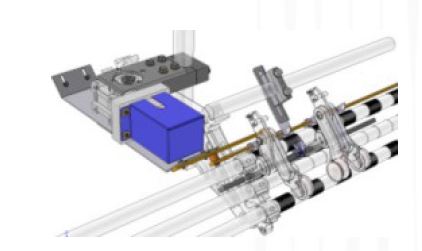

Core Yarn System

Lakshmi Caipo proudly presents hTcS to Indian market which is a unique attachment which make soft and hard core yarn. Core Yarn means a combination of a filament covered by fibers. In order to get the filament core completely covered, it is a must to keep it always aligned respect of spun fibers, so that it is hidden and wrapped by them. This can be achieved only with the use of a guiding mechanism ensuring the relative position of the core related to spun fibers. Without this, resulting core yarn will be rejected due to improper centering.

ADVANTAGES OF HTCS

- 100% Electronic Elastane Control

- Electronic Pre-tensioning

- Automatic adjustments with insertion of core in from 1.01 to 7 times

- Separate Motor for Traverse mechanism

- Lycra Stop motion is based on negative driven system which makes accurate in case of lycra missing.

- Roving Stop Motion and Lycra Lift handle

TRAVERSE DRIVING SYSTEM

- Providing controlled traverse to guiding system separate from original traverse

- Increasing the life of cots and aprons

- System designed for upgrading existing machines as it does not depend on ring frame’s traverse

- High precision and control of traverse motion to keep filament centering

LYCRA DETECTOR

- The new individual lycra detector with high intensity LED breakage indication

- The rotation of roller is measured and if there is a roller stop, immediately the LED indicates the absence of lycra and this avoid even a single meter of faulty core yarn

- Our latest development in the field of detection is efficient with an immediate detection, to minimize production of faulty yarn

- Ergonomically designed and fully integrated in the guiding set

- No disturbance to operation, Simple to operate and reliable

Roving Stop Motion

- Connected to lycra guide sensors, and stops roving feeding where the lycra breakage is detected.

- A special rotating wedge is inserted between top and bottom feeding rollers to avoid roving to be processed.

- Once operator attends the spindle, to simply press the button to release rotating wedge and start the roving feeding.